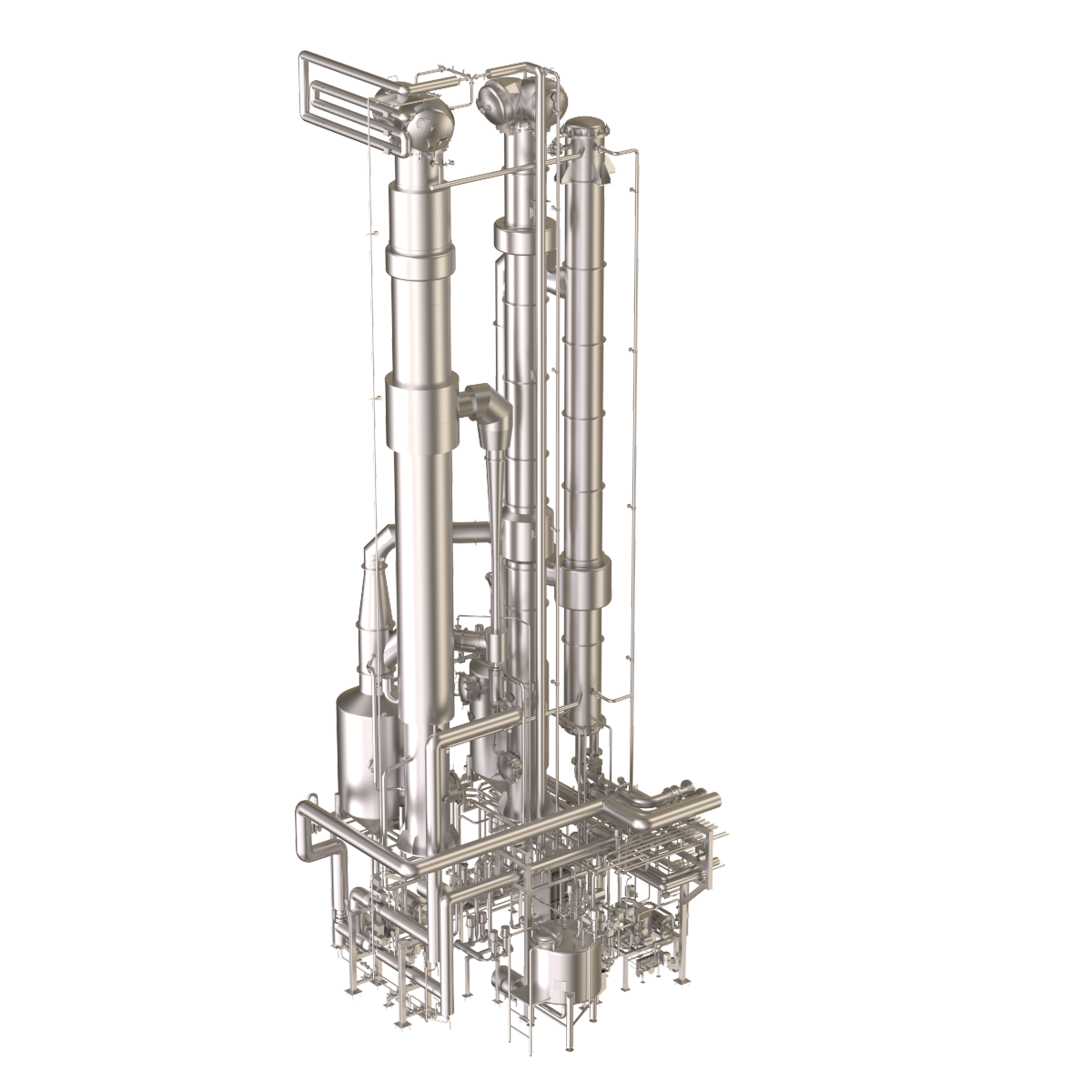

RELCO MVR and TVR Evaporator Systems

Heat Processing Equipment, Dryers

Information

Our MVR and TVR evaporator systems are designed with maximum flexibility to concentrate a wide variety of dairy products to a high total solids percentage.

RELCO®’s Evaporator is specifically designed to evaporate a variety of milk products, including skim and whole milk, whey, and permeate. Pre-evaporators are designed for a feed concentration generally between 6% and 24% total solids and will concentrate up to 35% to 45% total solids, depending on the application. From there a finisher is used to concentrate to higher solids, up to 62% total solids. Operating temperatures of each stage are controlled to maintain optimum product quality. RELCO can utilize MVR and/or TVR technology for each stage of evaporation.

Features & Benefits

• Generous surface area is used in each calandria to promote longer run times with increased efficiency

• Each calandria is divided into several passes as required to allow greater tube wetting rates, promoting longer run times with increased efficiency

• Turbofans are selected for large pressure rise with oversized motor, allowing for longer run times while using only the energy required

• Evaporator balance tank is integrated into the calandria base for reduced equipment footprint

• 316L product contact surfaces are available and sometimes required based on the application to lengthen the service life of the evaporator